For the past 40 years, RF-SMART has been delivering advanced mobile solutions for distributors, manufacturers, and retailers worldwide. We’ve spent that time forming a deep understanding of our supported ERPs and helping our customers improve their warehouse operations. Now, we are taking that knowledge to the next level - automation.

What is Warehouse Automation?

au•to•ma•tion – is the art and science of moving, storing, protecting and controlling material or inventory

If our long-term goal is to help our customers get to a fully automated warehouse, it means we want to help with:

- Moving Inventory: You have the correct amount of material at the right time and place and are able to move it faster through the supply chain. This is the main reason customers implement automation projects.

- Storing Inventory: Offer a buffer between people and machines

- Protecting Inventory: Includes packaging and protecting against damage and theft

- Controlling Inventory: Includes the physical orientation of items, sequencing, or space between materials. You want to be able to control the space of material on a carousel or how much of an item is being manufactured so you don’t make too much or too little.

The History behind Warehouse Automation

In less than 50 years, we’ve now entered the 4th industrial revolution of today with the concept of Internet of Things (IoT) – We now can take that PLC, add Wi-Fi, and it’s now a connected device. These devices are becoming aware of each other, interconnecting and communicating. Now we need a more efficient way to control them and the data they are capturing.

What’s the plan to Achieve Warehouse Automation?

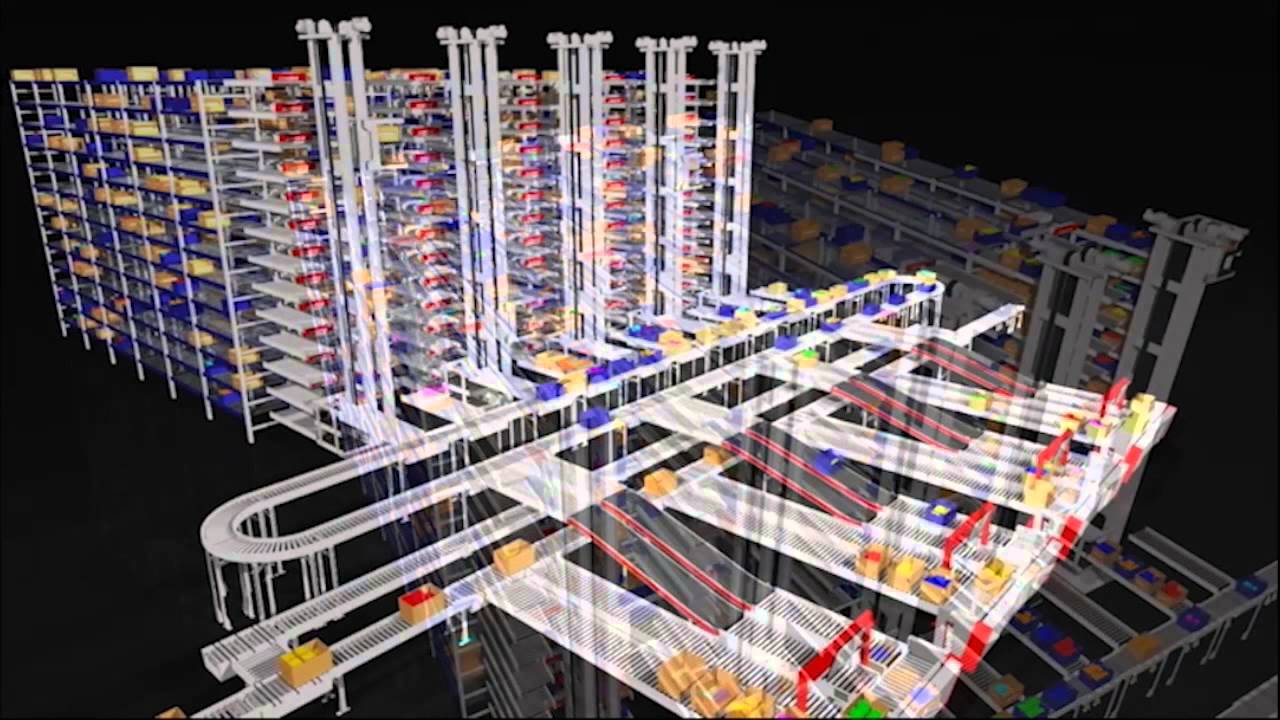

From Pick to Light systems and RFID, to carousels, cranes, palletizers and other robots – RF-SMART is looking to help companies implement automation equipment utilizing our already reliable integration to our supported ERPs. Building custom integrations can be very time-consuming and expensive – and you often need separate integrations for each machine. RF-SMART’s Warehouse Automation Module eliminates the need for custom integrations. Your machines can communicate with your ERP in real-time and update material movement and inventory changes.

Our goal is to transform our Customers in even more significant ways and work on a wide range of projects that help them solve their biggest business challenges. We’re ready to take on the final frontier … at least in the warehouse.

Ben McDonald is the Vice President of Products for RF-SMART. He has been crafting software solutions and motivating fellow technologists for 18 years after graduating from Georgia Tech with a bachelor's in computer science. He resides in Jacksonville with his wife and 3 kids.