Used extensively in manufacturing, retail and distribution environments, barcode scanning has become synonymous with convenience, increased accuracy and operational gains. But like most things, you can often take something good and make it even better. With barcode scanning, it's called parsing. Today we’re sharing tips for leveraging barcode parsing throughout your operations to increase efficiency.

This Q&A is part of our YouTube series, Q&A with RF-SMART. This series focuses on industry tips, best practices, and RF-SMART company culture. To receive notifications about new videos, you can subscribe to our YouTube channel.

Q: First of all, what is barcode parsing?

Essentially, it is a quick way for users to scan one barcode versus many. A barcode can contain more than just one piece of data about that item or service. Instead of multiple barcodes with a single chunk information, using parsing with a global standard like GS1-128 means a number of data points can be covered.

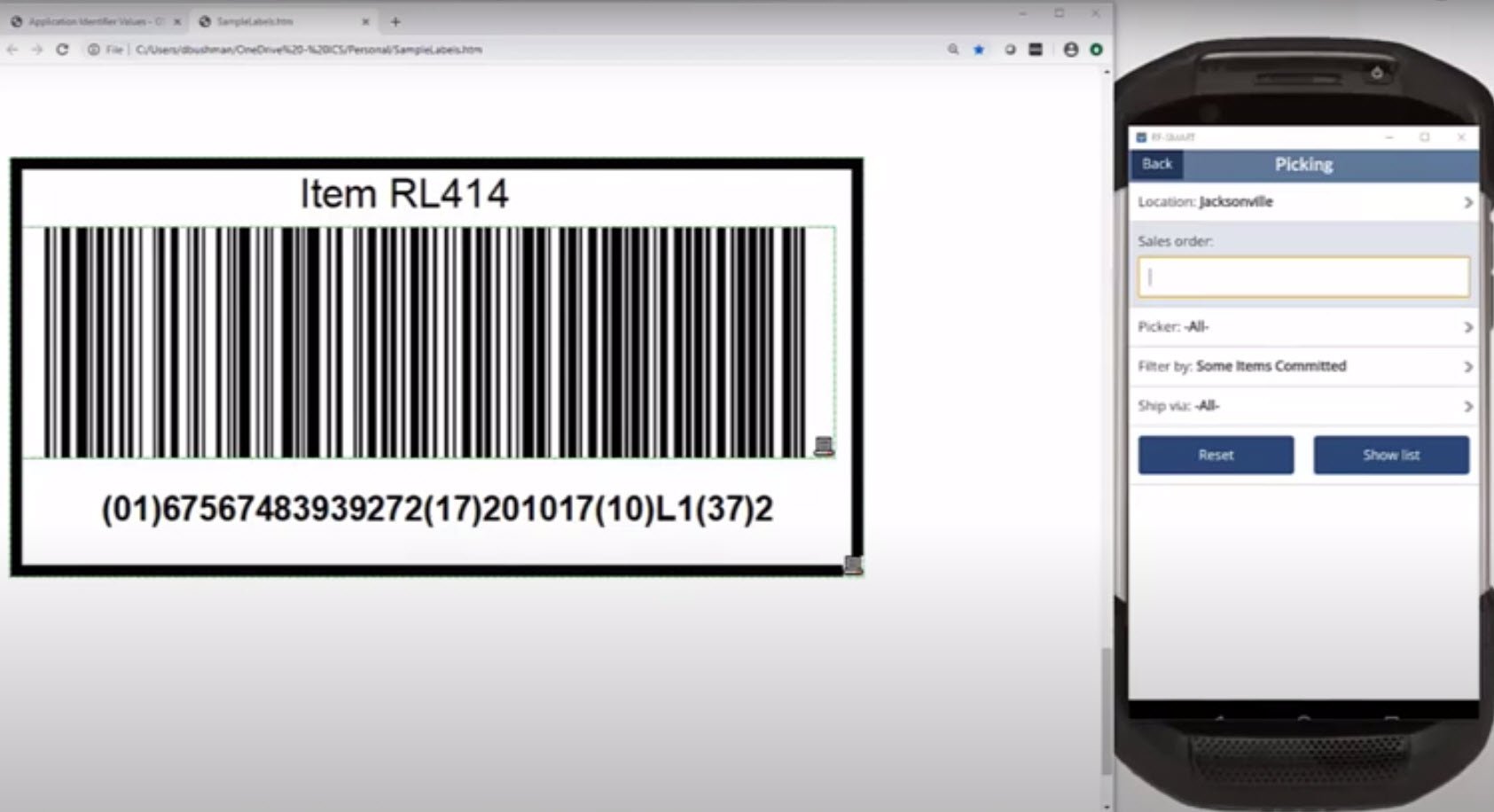

How this information is extracted from a single scan depends on the complexity of the barcode and how many application identifiers are embedded in the barcode. Application identifiers are numbers that break the barcode into meaningful segments - for example: item code, serial or batch number and expiration date in prescribed universal format.

Q: How does barcode parsing work?

When barcode parsing is switched on, the barcode is formatted to use the application identifiers, which point to pre-set universal format. The hardware scanner is able to take one scan and produce multiple characteristics about that item.

For example during a sales order picking process, you would want to collect information about the product that is being picked such as item number, lot number bin and quantity – each one of these could have their own barcode individually. By taking advantage of barcode parsing and having the application identifiers set up in a single barcode, it takes only one scan with the barcode devices to capture all that information as it is embedded in the barcode.

Q: What problem does parsing solve?

In a nutshell - it can save time. Using a global standard allows for the same data to be parsed (ie. translated) instantly by any barcoding device that has access to the library. Parsing facilitates the immediate data availability for that item and can used across multiple devices and barcode readers with the same uniform result.

Q: Where is barcode parsing used?

The most common place is in goods receiving, where it can be labelled as a raw material with the supplier information and the date received with SKU and Unit of measure - all visible from a single scan. If the supplier applies barcodes to their dispatched products and adheres to the GS1 parsing global standards, then the items can be immediately receipted into stock with one single scan. This can be a valuable time saver.

In manufacturing, the barcode can contain data like SKU, Sales Order, Batch, Lot or Serial and work order information. It can even direct where to be stored in which warehouse location or bin. With packing, the barcode can indicate which line on a sales order it is fulfilling and what quantity is required.

Q: What is an example of a customer leveraging barcode parsing?

A medical equipment company, who is a customer of RF-SMART, leverages their relationship with vendors that support GS1. This means most of their incoming goods are already barcoded at receiving, which leads to immediate time savings and increased accuracy. However, if a different supplier is not using the GS1 to produce barcodes, they can use RF-SMART to produce those labels as well.

Interested in learning more tips for our Q&A series?

Get a monthly recap of our latest Educational Content.

© 2025 RF-SMART. All rights reserved. Privacy Policy