Inventory Cycle Count

THE DEFINITIVE GUIDE

This guide on the Inventory Cycle Count will provide an overview of strategic counting processes, functions, and best practices for inventory control. This guide will review cycle counting techniques that can increase efficiency and accuracy across your supply chain operations.

Cycle Counting is a popular inventory management technique that can replace once-a-year counts and inventory auditing by counting specific items on a more regular basis.

Maintaining the accurate number of items in your inventory management system is mission-critical for today’s modern supply chain. Exact on-hand quantities are needed for inventory control and production planning, as well as supply chain management.

This will allow you to execute an efficient fulfillment process and ultimately ensure customer satisfaction. One way to maintain that inventory accuracy is to implement a Cycle Count process.

There are many ways to perform a Cycle Count, but how do you determine which process is best for your warehouse? Below is a breakdown of Cycle Counting best practices, different counting types and how Cycle Counting fits in.

Manual Counting

A Manual Count is often completed with pen and paper and/or in an Excel spreadsheet then the data is keyed into a computer. Inventory adjustments are made after the count is completed. There is the potential for mistakes due to miscounting the number of items in an area, recording the data in a confusing way, or inputting the data incorrectly. This could also lead to the need for extra inventory auditing to resolve discrepancies created in the inventory management system after an inaccurate count.

Mobile Counting

With Mobile Counting, everything in the process – item counting, data review, inventory adjustments, approvals, and more – all happen in the same system at the same time. This decreases the risk of inaccuracies significantly.

There are two counting categories within Mobile Counting:

- Physical Inventory Counting (sometimes referred to as wall-to-wall, annual count, stock take, or inventory auditing) can be performed using a directed, scheduled, or manual approach. Advanced physical counting solutions do not require a pause in warehouse operations.

- Cycle Counting Programs are warehouse management techniques where a subset of inventory is counted in specific locations, bins, items, and days, on a recurring schedule. When used with the right inventory management system, it allows visibility into product location, movement, and related employee activity at all times. Like physical counting, advanced cycle counting also does not bring a need to stop warehouse operations.

Why is Cycle Counting Important?

Every product you carry in your warehouse has value. Keeping an up-to-date picture of your stock through cycle counting carries a significant impact on overall inventory cost in your organization.

With consistent cycle counting, ongoing counts are set to update and match inventory records at any point of the year they are carried out. With this method, your company can have the most up-to-date, accurate view of the number of items in your warehouse and where they are located at any given time.

Ultimately, inventory cycle counting can help recognize and correct discrepancies in your stock records. Successful inventory cycle counting leads to fewer human errors and increased accuracy.

Customer Experience

"Before NetSuite and RF-SMART, we couldn't give an exact measure of inventory accuracy. But with RF-SMART as our consistent system of record, we have been closing the inaccuracy gap monthly. Our inventory is currently 99.97% accurate, and we have seen that level sustained over time. This critical aspect of our business is under control."

Donald Cheng, VP Operational Excellence & Business Systems for Kateeva.

How do You Get ROI with RF-SMART?

Try Out Our ROI Calculators Below to Find Out!

1) Keeping track of inventory movement

Cycle counting increases inventory accuracy, it can identify inventory issues faster and reduce the need for inventory auditing.

Many companies start out with paper-based systems, like RF-SMART customer Kateeva. They did not yet have an inventory management system in place, so everything was done manually. Counting could take hours, which often meant they get done quarterly, at best.

For Kateeva, there was a significant lag between data points for their inventory management and accounting systems, which is common for teams with manual processes. This made it impossible to know the number of items they had, where they were, and when they got there.

By implementing RF-SMART's Cycle Counting, Kateeva can now run counts on a dependable schedule and count double the inventory in 50% less time.

2) Minimizing risk for inventory discrepancies

Cycle counting reduces the risk of human error by performing more consistent daily counts that automatically update every time an item is scanned. This eliminates staff having to physically rope off areas that might get tampered with after manually counting.

RF-SMART customer Rhino-Rack used daily cycle counts to catch inventory discrepancies sooner rather than later. Since accurate inventory counts are the basis for all other inventory processes, such as picking, packing, and shipping, those inventory discrepancies were impacting their bottom line.

With RF-SMART, their new daily counting processes ensure their inventory levels are accurate, so less energy is spent looking for items and more orders are picked. These changes have also had upstream impacts in their business, helping keep the finance department satisfied by trusting that the best control measures are in place.

3) Improving customer service and warehouse efficiency

By focusing your efforts on improving your warehouse operations, you are laying the foundation for optimal customer service. When your customer is expecting a product, efficient order fulfillment and a timely delivery can positively impact your customers’ experience.

Using RF-SMART Cycle Counting, goodr has the ability to perform frequent counts for various products by bin or location. This has greatly increased the speed and efficiency of their counts, as all data is captured via the barcode scanner, and instantly transmitted into NetSuite. Counting with RF-SMART enabled them to keep their inventory data as accurate as possible, while decreasing user frustration.

Risks of Manual Counting

Improper counting processes are a gateway to inventory inaccuracy and order fulfilment errors, both of which are the enemy of any successful inventory management program and can have significant negative impacts on the bottom line of a business.

Let’s be honest – nobody enjoys counting inventory. If you’re currently performing inventory counts manually, chances are you are doing so with a large margin for error. The accuracy of a manual count is compromised as soon as your staff records an item’s quantity, location, or name incorrectly. This sets you up for a series of costly consequences, such as the accrual of obsolete stock or inaccuracies when fulfilling sales orders.

Additionally, manual counts are time consuming and will usually require you to pause all other warehouse activities – meaning order fulfillments come to a halt.

RF-SMART Cycle Counting Tip

RF-SMART Cycle Counting Tip

Break items down into small groups when addressing discrepancies.

After counting quickly and accurately, the margin of error is still there, which may cause significant inconsistencies. Group these discrepancies into very small, manageable counts and conduct a recount using a different employee

Cycle Counting Best Practices &

Popular Cycle Counting Methods

ABC Counting

Inspired by the Pareto Principle and the 80/20 rule, rank your items based on unique business criteria, including cost, quantity, or historical order value.

Create your ABC class definitions. Valuate your items, group them, and then assign them to a class.

- A items are high in volume or value and are counted quarterly.

- B items are counted twice a year and have higher turnover but may cost more.

- C items are slower moving and counted annually.

How to Do an ABC Cycle Count

Set up counts and approvals:

Ensure you define the items and classes to be included in each count. A and B class items should be scheduled for more frequent counts, thereby ensuring the accuracy of inventory. C class items are typically only counted once a year. Ensure all items in the ABC group are cycle count enabled.

Determine count frequency:

When attaching classes to a cycle count, ensure that you have entered the number of times you want the items in that class counted. This number is the minimum number of times it will be counted in a calendar year.

Generate count schedules and count sequences:

Schedule your count reviews, make any adjustments, and approve counts once complete. This should be done as soon as possible for accuracy.

Review your ABC analysis:

You should still review your ABC Analysis once a year to ensure inventory is still in the appropriate class. If items no longer meet class criteria, move them to another inventory classification.

Bin Sequence Counting

If the ABC counting strategy isn't a good fit for the type of inventory you manage, another option is to divide your warehouse into sections, then count them sequentially. A best practice is to randomize the order to avoid creating any predictability and limit the margin for error.

RF-SMART Cycle Counting Tip

Although a cycle counting program can work with or without bins, adopting bins in your warehouse can reduce the risk of discrepancies when the same item is stored in multiple locations.

Random Sample Cycle Counting

Completely randomize the SKUs you will count and assign each one a count date. This method will allow you to count all bins containing the same item in one go.

There are two types of random sample cycle counting:

- Constant Population Counting

Constant population is where a selection of items could be counted multiple times within a small-time frame due to staying in the group of all warehouse items. - Diminished Population Counting

Diminished population counting, on the other hand, excludes the items from being counted again until all items in the warehouse are counted.

Check Software Updates

Check Software Updates

Ensure you are operating with your solution's most recent software updates so you have the latest functions and features.

Start with Clean Data

Before you begin your first cycle count, it is important to do a wall-to-wall physical inventory count to ensure NetSuite is updated with the correct inventory numbers. Skipping this step will make your cycle counts inaccurate.

No Bins? No Problem!

When working with few to no bins in the warehouse, consider physically assembling your inventory as close together as possible. For stores that cross-merchandise items, knowing all item locations is critical. If you utilize shelf tags, a color dot on the tag can indicate a cross-merchandised item, making it easier for any recounts.

Organization is Key

From tidying up around the warehouse to adopting storage that works for your WMS, organized inventory facilitates an accurate count.

To assist with the counting process, we recommend you fully label your warehouse with items, locators, sub inventories, etc. Be sure to identify and leave items that have not been received or shipped from your ERP out of the count. Ensure items that you want to include in your counts are properly set up.

Analyze Warehouse Data

All inventory transactions should be reviewed to determine what kind of cycle program that best fits your needs (ABC, Bin Sequencing, or Counting Groups.) Create a stock count plan based on the type of cycle count you want to use.

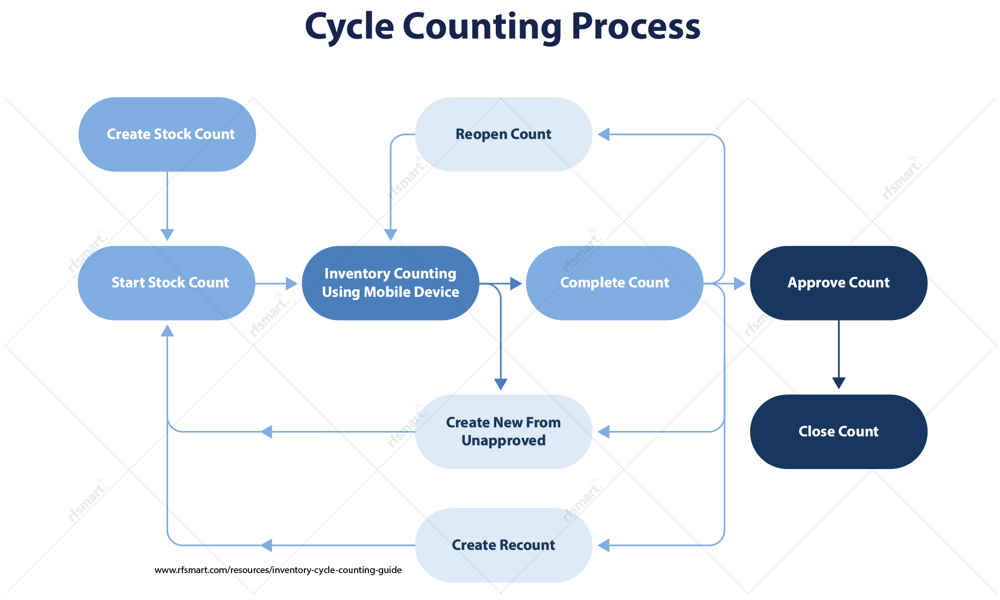

Initiate the Counting Process

- Create the Count

- Start the Count

- Perform the Count

- Complete the Count

- Approve the Count

- Create Recounts or New from Unapproved

- Close the Count

Ongoing Cycle Counts

Ensure you are completing the cycle counting at regular intervals to maintain accuracy throughout the year.

How Often Should You Cycle Count?

Since counting techniques, frequency, and inventory levels are unique to each business, the cycle count system in place should reflect your company’s needs to keep inventory accuracy high and minimize or eliminate a pause in warehouse operations.

With cycle counting, counts should be spread throughout the year, with each count being small enough to be processed on the same day. This can vary from business to business based on different types of inventory and frequency of orders.

Additional Cycle Counting Best Practice Tips:

- Give advanced notice that a Physical Inventory is occurring

- Prior to performing the Physical Inventory, ensure all transactions in your WMS are entered/up to date

- During the Physical Inventory, ensure no other transactions are processed as these will not be considered in the Physical Inventory adjustments

Customer Experience: Industrial Control Solutions

"Using QuickBooks was very manual. We would use print outs and manually complete the inventory and then import the data back into QuickBooks. We’re seeing the most time by completing weekly cycle counts with RF-SMART."

Cameron Davis, Operations Manager

Industrial Controls Solutions previously took three weeks for annual inventory counting with manual printing, importing, and paper inventory management through QuickBooks. With RF-SMART, their team can now complete their annual count in 2 days. Cycle counting with RF-SMART also eliminates the need to cordon off sections of inventory as it is being counted.

![]()

Built in NetSuite

The most effective way to conduct inventory counts is by utilizing a cloud-based, mobile barcoding solution that is built directly on your ERP platform. RF-SMART leverages our proven Built-in-NetSuite, native warehouse management system for accurate, efficient cycle counting.

Eliminate Halt to Warehouse Operations

Halting warehouse operations is inefficient and costly – time is money. With RF-SMART, you do not need to pause operations to conduct a physical inventory count or cycle counting. This is key, so whether you use cycle counting exclusively or in conjunction with physical inventory counting, you never have any downtime.

Multiple Forms of Counting

RF-SMART has multiple counting functions available to RF-SMART customers. This includes options to help warehouse staff directly navigate to items/bins or do blind counts as well as scan-only options for each of those functions. These functions can be tailored to items that need to be individually counted or counting overall inventory.

Real-time Review of Inventory Count Progress

RF-SMART enables managers and supervisors to review in real time how far along the counts are in progress, variances, and errors – and even ask those questions while warehouse staff are counting. The functionality allows flexibility to sort by variances and approve the inventory adjustment value when someone is assisting you during the approval process.

Ease of Use

With RF-SMART's intuitive user interface, automated features, and detailed analytics, you know exactly where your inventory is and who puts it there at all times. It’s easy to implement, easy to use, and easy to train warehouse staff to ensure your counting processes are consistent. You can cycle count from the same place you are scanning – no toggling to other systems!

“Because of RF-SMART, I can now spend the holidays with my family. In the past, we worked long hours during our busy season doing our annual count, but there’s no need for that now. We have on-going cycle counting all year long so there’s not a rush at year end.” - RF-SMART Customer in Ecommerce Industry

Customer Experience

Prior to implementing RF-SMART, NewAir completed annual physical inventories, which resulted in large adjustments to inventory. Today, they have one person completing daily cycle counts, which alerts the NewAir team of any inaccuracies within a bin or location quickly.

"With RF-SMART, we have visibility into our inventory we didn't have before. We can easily settle any discrepancies."

Janneth Guevara, NetSuite Administrator

Stock Count Planning

Different businesses might want to count in different ways, so depending on how you want to count, divide inventory, and divide physical spaces, RF-SMART enables you to save counting configurations for repeated use - no more creating counts on the fly.

Designed to assist with inventory cycle counting (continuous and ongoing), Stock Count Planning allows you to create a comprehensive inventory counting program, and then configure and save individual stock count plans as needed. Count plans can then be set to run automatically or run ad hoc by users to keep cycle counts on time and accurate, whether you’re in the warehouse, the office, or even on vacation. Each count plan represents a portion of inventory, which needs counting on a regular basis (daily, weekly, monthly, quarterly, yearly, etc.).

Counting Groups

While you can configure the count sheets or count forms with basic and custom filters, for even more flexibility and control, you can filter your cycle counts by Item Counting Groups or Bin Counting Groups.

- Item Counting Groups: Allows the customer to configure groups of items to be counted and assign those items to the counting groups. Items can be associated manually or by importing CSV files into NetSuite.

- Bin Counting Groups: Allows the customer to configure groups of bins to be counted and assign those bins to the counting groups. Bins can be associated manually or by importing CSV files into NetSuite.

MASTERCLASS

Year-End Counting Best Practices

This 60 minute masterclass recording covers counting best practices for those using NetSuite. It includes a demonstration of counting using RF-SMART and a Q&A session.

Learn about:

- Best practices and tips for counting, such as implementing item classifications

- The benefits of cycle counting

- How using a mobile solution can make your counts more accurate and efficient

.jpg?width=1080&height=1080&name=How%20to%20Prepare%20for%20an%20Annual%20Inventory%20Count%20(1).jpg)